青岛建华食品机械制造有限公司

青岛建华食品机械制造有限公司成立于2000年,是一家专业生产猪、牛、羊、家禽屠宰设备及分割自动生产线的专业厂家。公司下设山东省企业技术中心、畜禽屠宰加工设备工程实验室、青岛市工程研究中心、青岛市畜禽屠宰设备研发专家工作站、铸造公司、安装公司、售后服务公司、五个生产车间、三个厂区,占地面积共计150亩,建筑面积7万平方米,年生产值超3亿人民币,拥有职工285人,其中各类专业工程技术、工艺人员94人。

建华人着眼做大做强、做精做专

把目标瞄准了主持和参与国家标准、行业标准的制定

建华公司先后主持和参与多项国家标准和行业标准的制定。通过参与标准制定,大大提升了企业知名度,营造了品牌效应。多年来,通过持续不断地梳理、挖掘、整合,公司现已获得多项国家授权专利。

国家标准

行业标准

发明专利

实用新型专利

产品

公司目前的产品包括:猪、牛、羊、家禽屠宰设备、分割设备等,广泛应用于杀猪吃肉产品领域。

猪屠宰设备

机械手式猪自动半劈机、框架式猪自动半劈机…

牛屠宰设备

翻板箱、扯皮机、高压胴体冲淋、S形赶牛道…

羊屠宰设备

羊单柱扯皮机、羊刨毛机、羊V型限制输送机…

家禽屠宰设备

活禽悬挂输送线、A型脱毛机、螺旋预冷机…

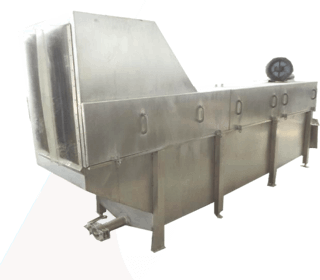

分割设备

分割输送机、三级肉类分割线、双层肉类分割线…

制冷工程

叉档消毒箱、不锈钢叉档箱、不锈钢偏轨道…